Dhiman Group offers complete production plans for making liquid filled candies. The process of liquid filled candy making can be made fairly simple under the guidance of Dhiman Industries. The process of liquid filled candy making starts similar to the hard-boiled candy making process. As the name suggests liquid food candy making is the process of having individual pieces of candies filled with any sort of edible liquid such as fruits syrups chocolates liquid chocolate etcLiquid filled candies have had a huge fan following in regions across the Gulf and the Indian subcontinent. Truly an innovative introduction in the market, with the liquid filled candy machines the manufacturer can benefit from a superior price point while having innovative flavours with very few changes in the manufacturing process.

Similar to any process of candy making the first step in the liquid filled candy making starts with dissolver processing the sugar syrup that is cooked on in a specific temperature and in the cases of hard-boiled candies vacuum pressure is applied. Now liquid filled candies can also be implemented in the process of toffees or eclairs where liquid filled chocolates can be filled into hollowed toffees.

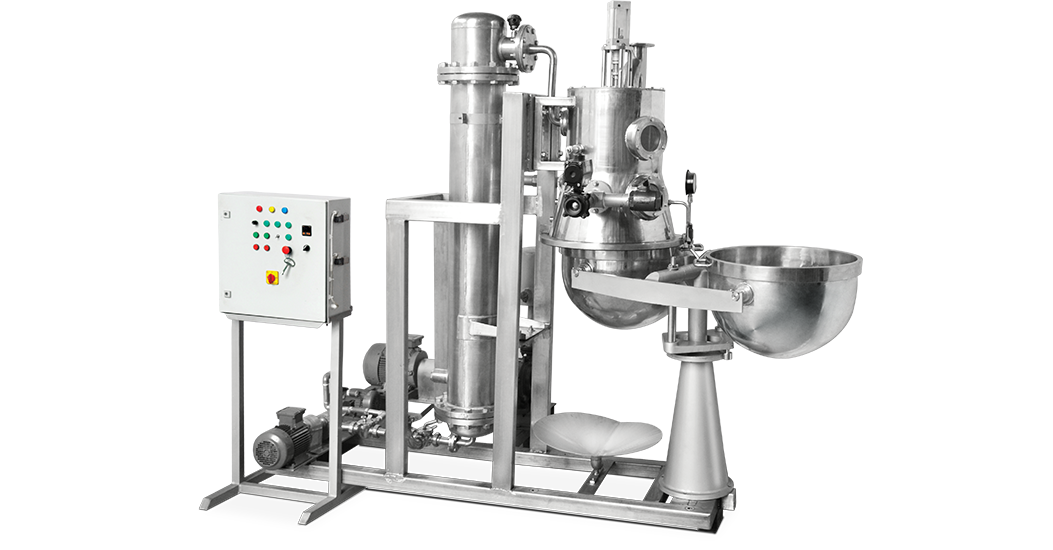

The Liquid filling machine or the Liquid Filled Candy Machine has been rightfully designed to pump the liquid mass continuously without any displacement and bubbles. The storage hopper is heat-jacketed to ensure continuous flow of liquid ensuring that even thicker or liquids of grainy consistency can even be pumped in easily for a constant and uninterrupted flow of the liquid making sure that no single candy

Without the need for a rigorous setup or change over, an operator can effortlessly adjust the amount of liquid being filed from the adjoining control panel that can be supplied with the machine. This feature makes sure that the amount of liquid being filled in each and every candy is constant and helps prevent any unnecessary imbalances and variations in the raw material of your products and even in the composite of the product. Simple operations such as these help your production facility become more efficient without the need to intervene in the production process.

We, at Dhiman Industries make sure that the end customer does not face any difficulties while operating, changeover or even while cleaning the machine. To support this reason, the Liquid filling machine or the Liquid Filled Candy Machine has been appropriately designed to facilitate an easy and thorough cleaning of the machine. This factor sustains a comprehensive cleaning process and also helps prevent any cross-contamination if the manufacturer decides to use the same machine but with different liquid fillings.

The Liquid Filled Candy Machine is best suited to be set up with the Batch Forming and Rope Sizing Machine.

The purpose of a Batch Forming Machine is not just to form the batch of confectionery, but Dhiman Industries’ recommended model BRS-90 Batch Forming and Rope Sizer Machine helps to form the confectionery mass while also sizing the same for the next part of the confectionery making process. Your confectionery mass requires this equipment because without it the next machine- which ideally has to be a forming machine cannot function appropriately if the batch has not been formed and sized properly.

The Liquid Filling Machine is interconnected with our Batch Roller & Rope Sizer Machine BRS-90 that feeds liquids such as white chocolate, dark chocolate, caramel, and others in the toffee mass before being formed with the uniplast machine. This whole operation takes place at a phenomenal speed, so much so that every minute the DUP-800 Uniplast machine is able to form toffees up to 800 kgs/hour.

The Liquid filled candy Machines by Dhiman Industries have been created with the goal of producing safe and high-quality confectionery items while maintaining total production efficiency and quality assurance standards, which are essential in any food processing facility. To comply with the worldwide standard of food safety and food defense, Dhiman Industries as a standard practice only utilizes stainless steel- especially for food contact parts.

Owing to this you can easily explore our website and inquire about our world-famous machines but we recommend dropping us an email or a message to get in touch with our sales representative for a one-to-one personal experience. This will help us guide you with the best possible solution for YOUR confectionery products.

Liquid filled candy manufacturing, as the name implies, is the process of filling individual pieces of candy with any consumable liquid, such as fruits syrups, chocolates, liquid chocolate, and so on. Liquid-filled candies have a dedicated following throughout the Gulf and across the Indian subcontinent. With the liquid filled candy machines, the manufacturer may benefit from a superior pricing point while having unique tastes with very little changes in the manufacturing process, making it a really innovative entry to the market.

Dhiman Group provides complete manufacturing plants for liquid-filled candies. Under the supervision of Dhiman Industries, the process of creating liquid filled candy can be made quite straightforward. The procedure of manufacturing liquid filled candy begins similarly to the process of making hard-boiled candy.

The Liquid Filling Machine, also known as the Liquid Filled Candy Machine, is designed to constantly pump liquid mass without any displacement or bubbles. The storage hopper is heat-jacketed to maintain a steady and uninterrupted flow of liquid, allowing even thicker or gritty liquids to be pumped in easily for a consistent and unbroken flow of liquid, ensuring that no single candy is lost.

The Liquid Filling Machine is attached to our BRS-90 Batch Roller & Rope Sizer Machine, that feeds liquids like white chocolate, dark chocolate, caramel, and others into the toffee mass before it is created using the Uniplast machine. This entire process occurs at lightning speed, with the DUP-800 Uniplast machine capable of forming toffees ranging up to 800 kg per hour. Dhiman Industries’ Liquid Filled Candy Machines are designed with the purpose of manufacturing safe and high-quality confectionery while preserving entire production efficiency and quality assurance standards, both of which are critical in any food processing facility.